Sitemap

Careers

Download

Contact Us

© 2024 NGK BERYLCO. All rights reserved.

|

B25 HM |

B25 HMB |

|

|

|

|

Alloy |

Type |

Temper |

Tensile Strength (Mpa) |

90° bending R/t |

|

|

Long. |

Trans. |

||||

|

Berylco 25 CuBe2 CW101C C17200 |

Type B |

1/2HMB |

830 - 930 |

0.0 |

0.0 |

|

|

HMB |

930 - 1030 |

1.0 |

1.0 |

|

|

|

XHMB |

1070 - 1210 |

2.0 |

2.0 |

|

|

|

XHMSB |

1210 - 1310 |

3.5 |

6.0 |

|

|

Type S |

HM-Type S |

960 - 1040 |

0.5 |

0.5 |

|

|

|

XHM-Type S |

1060 - 1220 |

1.0 |

1.0 |

|

Typical R/t of 0.15mm thickness samples

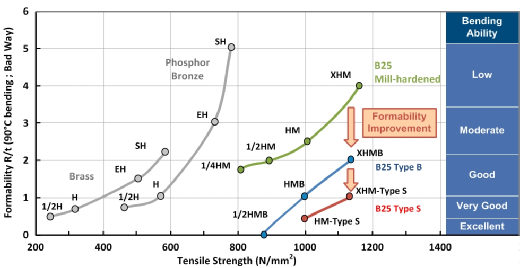

Formability of New NGK Berylco Strip products

Comparison of bending formability

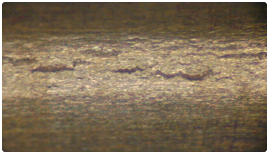

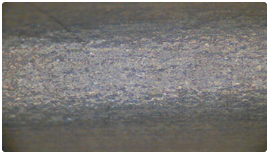

Comparison of bending formability test of B25 HM (standard) and B25 HMB (New Grade ‘Type-B’).

Photos show the 90º bending test results (Bad Way, R/t = 1.0, thickness 0.2mm). There are micro cracks on the usual product B25 HM, but new grade B25 HMB has no cracks. Good Formability is achieved in new grade ‘Type B’ and ‘Type S’. Both alloy tensile strength is equal to 1000 N/mm².

New Alloys - Better formability at equal strength

Mill-hardened Alloy B25 ‘Type-B’ and ‘Type-S’

Features

New grade ‘Type-B’ and ‘Type-S’ mill-hardened Berylco 25 have been developed by refinement of the manufacturing process for improved formability.

The bend radius ratio(R/t) of ‘Type-B’ is half that of the usual mill-hardened alloy.

The bend radius ratio(R/t) of ‘Type-S’ is one quarter that of usual due to crystal-grain-size-control.

Mill-hardened alloy is pre-aged (hardened) in the mill. Using mill-hardened alloy frees our clients from the troublesome aging process.

.

Products

| Introduction |

| History |

| Activities |

| Quality |

| Environment |

| R&D |

| Inventory |

| Satisfaction clients |

| Management |

| Certificates |

| Management |

| REACH & RoHS |

| Recycling |

| Strip |

| Wrought |

| Wire |

| Chill Vents |

| Safety Tools |

| Beryllium |

| Special products |

| Brochures |

| Products |

| Properties |

| Alloys |

| Heat-Treatment |

| Spring & Miniaturisation |

| Formability |

| Properties |

| Alloys |

| Products |

| Heat-Treatment |

| Plastic Industry |

| Introduction |

| Advantages |

| Design |

| Properties |

| Products |

| Alloys |

| Products |

| Information |

| Markets |

| Applications |

| NGK Berylco Worldwide |

| NGK Berylco Europe |

| Where to find us ? |

| Careers |

| Contact |

| Events |

| News |

| Links |