Sitemap

Careers

Download

Contact Us

© 2025 NGK BERYLCO. All rights reserved.

Characteristics of NGK BERYLCO alloys

High Strength, Moderate Conductivity System

Berylco 25 alloy, UNS C17200, can attain mechanical properties up to 1400 MPa UTS and hardness of 420 Vickers. Berylco 33-25, UNS C17300 is the free machining version with the same characteristics as Berylco 25. At a moderate conductivity of 25%, these alloys offer the best wear resistance, fatigue strength, and hardness available in the copper alloy system.

High Conductivity, Moderate Strength

Berylco 10 and 14, UNS C17500 and C17510, can attain conductivity over 45% IACS and strengths up to 970 MPa UTS. This combination of properties make these alloys ideally suited for heat dissipating modules, resistance welding components, and other electrical applications.

Machinability

Beryllium copper can be machined into intricate shapes. Its machinability in the age hardened condition is comparable to many other copper base alloys, and better than stainless steels. Its dimensional stability is far superior to any other copper base alloy.

Abrasive Wear Resistance

Beryllium copper offers attractive wear resistant properties compared

to other copper base alloys and many ferrous alloys because of its

complex oxide transfer wear films.

The high strength of age hardened parts makes them capable of

sustaining bearing loads far in excess of other copper base alloys

and gives the added advantage of compatibility with high hardness ferrous alloy shafts.

Corrosion Resistance

Beryllium copper has corrosion resistance nearly equal to nickel silver and is not susceptible to hydrogen embrittlement.

High Fatigue Strength

Beryllium copper is known to have high fatigue strength because of its toughness and resistance to local deformation.

Non-Magnetic

The non-magnetic characteristic of beryllium copper alloys makes them extremely useful for housing sensitive detectors affected by magnetic fields.

Products

Contact Us

Contact Us

| Introduction |

| History |

| Activities |

| Quality |

| Environment |

| R&D |

| Inventory |

| Satisfaction clients |

| Management |

| Certificates |

| Management |

| REACH & RoHS |

| Recycling |

| Strip |

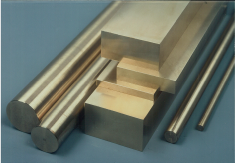

| Wrought |

| Wire |

| Chill Vents |

| Safety Tools |

| Beryllium |

| Special products |

| Brochures |

| Products |

| Properties |

| Alloys |

| Heat-Treatment |

| Spring & Miniaturisation |

| Formability |

| Properties |

| Alloys |

| Products |

| Heat-Treatment |

| Plastic Industry |

| Introduction |

| Advantages |

| Design |

| Properties |

| Products |

| Alloys |

| Products |

| Information |

| Markets |

| Applications |

| NGK Berylco Worldwide |

| NGK Berylco Europe |

| Where to find us ? |

| Careers |

| Contact |

| Events |

| News |

| Links |